Titanium Metals Corporation ("TIMET" or the "Company") reported its net income attributable to common stockholders increased 41% to $76.3 million, or $0.42 per diluted share, for the quarter ended June 30, 2007, compared to $54.3 million, or $0.31 per diluted share, for the quarter ended June 30, 2006.

The Company's net sales increased 13% from $300.9 million during the second quarter of 2006 to $341.2 million during the second quarter of 2007 due primarily to increases in average selling prices and favourable changes in product mix. Overall industry fundamentals and outlook continue to support a long-term favourable trend in demand for titanium across all major industry market sectors which has favourably impacted melted and mill titanium prices. Current trends in market demands have also resulted in a shift of the Company's product mix toward an increased proportion of mill products, including a higher mix of aerospace plate and sheet products, which require additional processing and resources as compared to melted products, but which also command higher sales prices. While volumes of melted and mill products declined somewhat compared to the same period in the prior year due primarily to the near-term effects of production delays with certain commercial aircraft and other adjustments to build-out schedules of certain customers, increased pricing on our products and a favourable shift in product mix more than offset the effects of the decline in aggregate sales volume.

Operating income increased 26% to $118.0 million for the quarter ended June 30, 2007 compared to $93.6 million for the quarter ended June 30, 2006. In addition to increased production costs associated with the shift in product mix to a greater percentage of mill products, cost of sales also increased due to higher costs of certain raw materials, including titanium sponge. Despite the increased cost of sales associated with higher raw material and production costs, profitability improved, as the favourable effect of higher average selling prices and a favourable change in product mix more than offset the effect of the higher costs. Operating income comparisons were also impacted by a reduction in other operating income in 2007, due primarily to $4.1 million of equity in earnings TIMET recognized in the second quarter of 2006 from our VALTIMET joint venture that was sold in December 2006.

The Company's sales order backlog at the end of June 2007 was $1.0 billion compared to $1.0 billion at the end of March 2007 and $0.9 billion at the end of June 2006.

Steven L. Watson, Vice Chairman and Chief Executive Officer, said, "We continue to see long-term favourable demand trends across all of our primary markets. Our facilities are operating at high capacity levels that improve cost efficiency, contributing to our record levels of operating income. While our near-term focus remains on maximizing our existing productive capacity through initiatives that emphasize efficiency, innovation and technological advances, we are also continuing our efforts to expand our productive capacity across all areas of our manufacturing operations. We are committed to maintaining the certainty, quality and reliability of supply to service the expanding needs of our current and prospective customers.

"Our 4,000 metric ton Vacuum Distillation Process ("VDP") sponge expansion in Henderson, Nevada commenced commercial production in April 2007, and we expect to be operating at full annual capacity of approximately 12,600 metric tons by the end of the third quarter of 2007. As part of our plans to assure our future supply of raw materials, we are continuing our design, engineering and site selection for a new VDP premium-grade sponge facility. We are also continuing to explore and pursue additional third-party long-term sources of sponge and scrap.

"Our electron beam cold hearth ("EB") melt capacity addition in Morgantown, Pennsylvania of approximately 8,500 metric tons, annually, is on schedule for an anticipated completion date of early 2008. We also commenced efforts to add a similar EB furnace at our Morgantown, Pennsylvania facility, scheduled to be completed in the last half of 2009. During 2007 we have also commenced construction of additional vacuum arc remelt ("VAR") capacity additions at our Witton, Morgantown and Savoie locations, all of which are expected to be completed by the end of the second quarter of 2008. Upon completion, these melt capacity additions will increase our EB melt capacity by approximately 107% and will increase our VAR capacity by approximately 34%. As we continue to adjust our long-term business plan in response to industry trends, we will consider more additions to our melt capacity based on our raw material sources and product mix.

"We have numerous other capital projects in process to improve and expand our productive capacity for scrap recycling and production of mill products. We also continue to evaluate opportunities to enter into long-term conversion agreements with third parties to address certain areas of additional or expanded manufacturing requirements as an alternative to the addition or expansion of our internal manufacturing capacity. Our ongoing and planned expansions of sponge and melt capacities, as well as our efforts to expand our key relationships with third-parties, allow TIMET to remain positioned to effectively utilize available resources to strategically invest in our business to achieve profitable growth and return on invested capital. We continue to emphasize initiatives that will increase our participation in downstream value-added products and services which are expected to provide strong operating results."

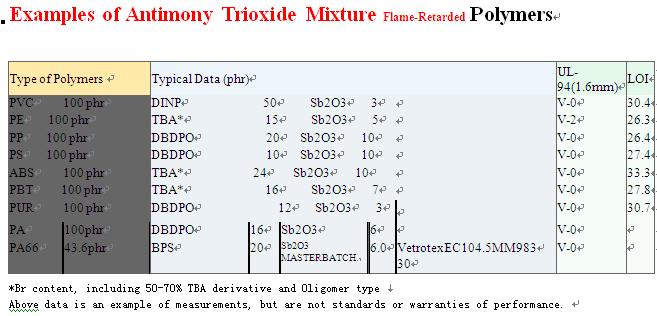

We can supply any quantity and any kind of Antimony products and fire retardant from stock.would you please inform us how many you need and your target price, then we will confirm ASAP. We are sincerely hope to do business with you and establish long term business relationship with your respectable company.

Look forward to hearing from you soon.

Best regards,

Sam Xu

MSN: xubiao_1996@hotmail.com

GMAIL: samjiefu@gmail.com

SKPYE:jiefu1996

Fire retardant masterbatch

0 comment:

Post a Comment