Luzenac will be presenting the Firebrake® ZB range at the K2004 trade show in October.

Firebrake® ZB is a boron-based fire retardant produced by Luzenac's sister company Borax and marketed by Luzenac since March 2003.

Used extensively in polymers such as PVC, polyamides, polyolefins and elastomers, Firebrake® ZB provides the following benefits:

flame retardant,

smoke suppressant,

afterglow suppressant,

anti-arcing and anti-tracking agent,

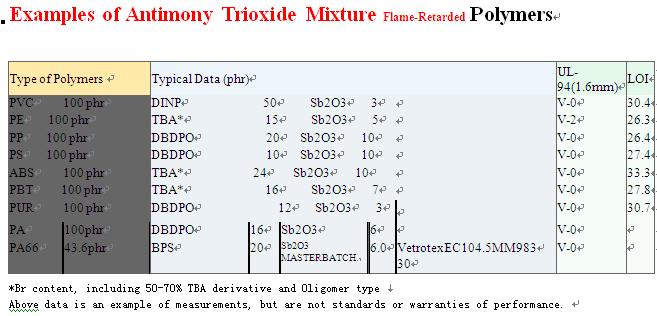

synergist of antimony oxide,

promotes char formation and prevents dripping,

can be used in both halogen and halogen-free systems.

Used in combination with metallic hydroxides, Firebrake® ZB can form a porous and hard residue during the combustion of the polymer matrix. In wire and cables, for example, this sintered residue is an important thermal insulator for the substrate or unburned polymer. It can prevent short-circuiting and sparking, as well as protecting the underlying insulation material. Partial replacement of ATH with Firebrake® ZB can result in significantly higher oxygen Index and better fire test performance in a UL94 test but only at high total loadings.

Moreover, the strong char formation with the elimination of surface cracks can prevent volatile gases from reaching the combustion zone. This ceramic residue prevents burning drips and delays oxidative pyrolysis.

The use of co-additives such as silicone, melamine phosphate, depending on polymer matrix, improves the performance of Firebrake® Zinc Borate / metal hydroxide combination.

In flame retardant systems using halogenated flame retardants and antimony trioxide, zinc borate can partly or completely replace antimony with less smoke and improvement of electrical material properties such as comparative tracking index.

In flame retardant PVC materials using antimony trioxide, partial or complete replacement by zinc borate leads to equivalent fire retardant characteristics with low smoke.

Luzenac is the world's leading talc producer with over thirty wholly owned mines and processing plants around the world. As global leader, Luzenac is committed to developing new talc grades that will provide polymers manufacturers with innovative and cost-effective solutions.

(Stand 8D48 - Hall 8)

Press Contact

Laura Jones

Luzenac Group

Tel: +33 5 61 50 20 20

Fax: +33 5 61 40 06 23

polymers@europe.luzenac.com

www.luzenac.com

Back

0 comment:

Post a Comment