The world’s most widely used flame retardant is alumina trihydrate (ATH).

Here’s how ATH works: At approximately 440°F (225°C), the three water molecules in alumina trihydrate are released in an endothermic reaction. The released water molecules quench the surface of the surrounding materials, thus providing flame retardance and smoke suppression.

Because alumina trihydrate contains no halogens or heavy metals, it is more environmentally friendly than flame retardants based on antimony metal or chlorinated and brominated (halogenated) compounds.

Lower compound viscosity and reduce cost with SB 30, SB 36 or SB 222, Huber’s lowest surface area and most affordable grades of ATH. These ATH grades have average particle sizes of 50, 25 and 14 microns, respectively, and the surface area is less than 1.3 m2/gram.

Increase flame retardant efficiency by using high surface area ATH products such as Micral ® 632 or Micral 932. The increased surface area releases more water molecules at high temperatures.

Narrow the particle size distribution with 1 micron Micral 9400 and chemically treated analogs. A narrower particle size distribution means fewer large particles and lower surface area. This is important for applications such as wire and cable.

Huber’s Hymod® M-9400 SP imparts improved mechanical properties, increased water resistance and improved processing.

Impart high flame retardant efficiency with low compound viscosity with a surface-treated ATH such as Hymod SB-432CM, Hymod M-632 SP or Hymod M-9400 SP. These treated ATHs will have lower mixing viscosity than their untreated analogs.

Increase compatibility with silicone rubber by using an ATH with Huber’s SP silane surface treatment. ATH treated with a reactive silane improves dispersion and increases mechanical properties. The hydrophilic end of the silane molecule is reacted to the ATH, thus reducing the silane’s water sensitivity. The other end is available to crosslink with the elastomer. Hymod M-632 SP and Hymod M-9400 SP impart improved mechanical properties, increased water resistance and improved processing. The average particle sizes are approximately 5, 2 and 1 micron, respectively, imparting excellent flame retardant efficiency.

Process at temperatures above 400°F (204°C) with Vertex® ST or Zerogen® 50SP surface-treated magnesium hydroxide. Magnesium Hydroxide provides flame retardance similar to alumina trihydrate, but it dehydrates at 550°F (288°C). Like ATH, it contains no halogens or heavy metals.

Vertex ST is a treated magnesium hydroxide that enables easy dispersion into elastomers. It does an excellent job

imparting flame retardance in thermoplastic polyolefins for single-ply roofing. Its untreated analog is Vertex 60. Zerogen 50SP is finer and more pure than Vertex ST, and is used in wire and cable applications.

src="http://pagead2.googlesyndication.com/pagead/show_ads.js">

Best regards,

**********************

DONGGUAN JIEFU FLAME-RETARDED MATERIALS CO.,LTD

Sam Xu 许彪

Sales Engineer

Tel: 86-755-83474911

Fax: 86-755-83474980

Mobile:13929211059

E-mail: xubiao_1996@hotmail.com samjiefu@gmail.com

Add: jiefu industrial park shuiping industrail district dalang town dongguan GD,P.R.C

WebSite: http://www.jiefu.com

blog:http://jiefuantimonytrioxide.blogspot.com

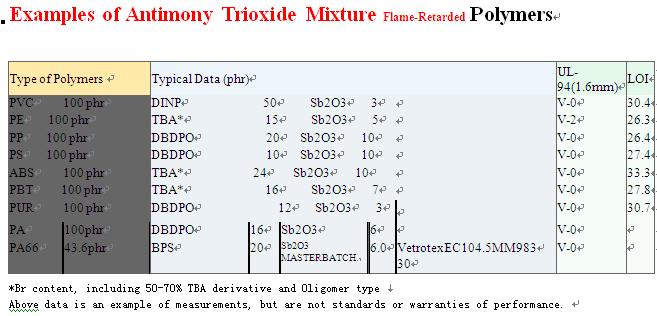

Export: antimony ingots,ATO,dust free ATO,ATO masterbatches EVA80.EAV90;PE80,PE90,PVC85,PP80,ETC, other flame retardant masterbatches,

¤ ╭⌒╮ ╭⌒⌒╮

╱-◥██◣ ╭ ╭ 工作顺利!天天开心! @-@

︱田︱田田| ╰----------------------

╬╬╬╬╬╬╬╬╬╬╬╬╬╬╬╬╬╬╬╬╬╬╬╬

0 comment:

Post a Comment