Manganese Nitride

Product Description

Spec:

Mn 88% min N 7% min

C 0.05% max S 0.05% max

P 0.01% max Si 1.0% max

Fe 0.50% max

Size: 28mm*33mm*55mm.

As manufacturer specialized in manufacturing of Antimony trioxide and flame retardant masterbatch, our company has the best quality products and most competitive price.continuously supply our products to America,Europe,Nippon,Korea and so on,Consistent high quality, Prompt delivery, Low cost.Welcome long-term agencies oversea.

Flame Retardant are substances that can be chemically inserted into the polymer molecule or be physically blended in polymers after polymerization to suppress, reduce, delay or modify the propagation of a flame through a plastic materials. There are several classes of flame retardants; Non-halogenated / Halogen-FREE (Ammonium Polyphosphate, Melamine Polyphosphate etc) flame retardants , Halogenated Hydrocarbons ( Chlorine and Bromine containing compounds and reactive flame retardants ), Inorganic flame retardants ( Boron compounds, Antimony oxides, Aluminium Hydroxide, molybdenum compounds, zinc and magnesium oxides ), Phosphorous containing compounds ( Organic phosphate esters, phosphates, halogenated phosphorous compounds and inorganic phosphorus containing salts ).

![]() Non-halogenated Flame Retardant

Non-halogenated Flame Retardant

Non-halogenated Flame retardant not only enhances its non-halogen properties, it also has excellent properties like environmental friendly, lower smoke, excellent water-proof aging, aging stability, low migration, excellent processing property and attractive performance.A wide and versatile range of applications, applies to plastics, rubber as well as coating industry.

![]() Antimony Trioxide

Antimony Trioxide

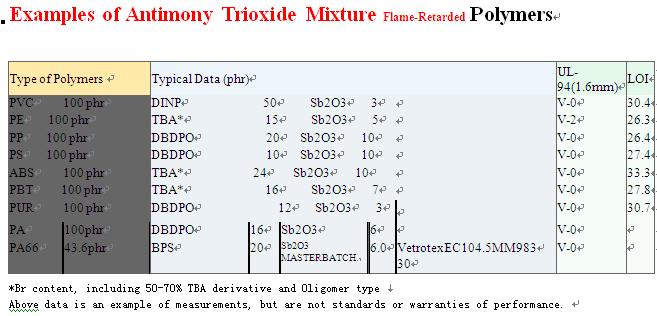

Antimony trioxide is used mainly in fire-retardant formulations for plastics ( PVC resin, Vinyl resin and other resins compatible to DOP ), rubbers, textiles, paper and paints. It is also used as an additive in glass and ceramic products and as a catalyst in the chemical industry.

![]() Deca

Deca

Decabromodiphenyl Oxide, belongs to a family of polybrominated flame retardant, is used polyolefins, styrenics, polyamides and thermoplastic polyester resins. Its end applications include elastomers, wire & cable, textile coatings, electrical & electronic equipment, automotive parts, construction materials, texture backcoatings and textile blends.

![]() Magnesium Hydroxide

Magnesium Hydroxide

Magnesium Hydroxide is white powder, very slightly soluble in water; decomposing at 350 C. It occurs naturally as the mineral called brucite or is prepared by reacting magnesium sulphate or chloride with sodium hydroxide. It is used in the refining of sugar, in extraction of magnesium metal, in the processing of uranium, and in the sulfite wood pulp process. It is an inert filler, flame retardant and smoke suppressant for plastics, synthetic rubber, reinforced polyesters, phenolics, and urethane foam. Magnesium hydroxide releases its 31% water when heated to above 325 C, which cools the product below flash point to reduce fire occurance. Medicinally it, in the form of a mixture ( milk of magnesia ), is also used as an antacid and as a osmotic laxative.

0 comment:

Post a Comment