|

|

As in the general flame retardant market, there is a desire to replace halogenated flame retardants in polyamides with halogen-free alternatives. This trend is driven primarily by the OEMs' desire to have an environmentally friendly image and concerns about the European regulation for waste of electrical and electronic devices disposal (WEEE), which requires separate treatment of halogen containing parts. However, with their established use and good cost-performance, halogenated flame retardants are still widely used in PA. Halogenated products include polymeric brominated flame retardants and OxyChem's chlorinated alicyclic compound. Halogenated flame retardants are typically used with synergists such as antimony oxide or zinc compounds. Non-halogenated flame retardants for polyamides include red phosphorus, melamine-based products and magnesium hydroxide. New phosphorus-based flame retardants seek to solve drawbacks of these more traditional non-halogens. Nanoclays are beginning to find use as anti-dripping agents in flame retardant packages.

The increasing need for improved thermal stability in many applications is driving growth of high-temperature polyamides and use of flame retardants with greater thermal stability. In Europe, high-temperature polyamides (HTPA), a segment of the high performance polyamide (HPPA) market, are expected to have a 12% compound annual growth rate from 2003 to 2010, predicts U.S. consultancy Frost and Sullivan in an August 2004 report. In electronics, the continuing miniaturization trend is driving HTPA growth. The European Union Reduction of Hazardous substances (RoHS) directive takes effect in 2006 and mandates that electronics manufacturers switch to lead-free solder systems. Because lead-free solder systems typically run 30-50°C higher than traditional lead systems, manufacturers must use both polymers and polymer additives with higher thermal stability. Moulders tend to process at temperatures even higher than those used for compounding in an attempt to increase production throughput, further increasing the need for flame retardant thermal stability. Thermal stability is also important for recycling in-plant regrind.

As parts become smaller, materials need both better thermal stability and higher flow properties. Flame retardants vary in their flow characteristics and have an impact on the material's final flow properties, notes Joe Andrews, global director of marketing at Great Lakes Chemical Company. Chip density also increases with part miniaturization, making a material's electrical properties increasingly important. The type of flame retardant used has a large effect on the Comparative Tracking Index (CTI), which indicates the relative susceptibility of polymers under electrical stress to becoming conductive at the part surface and igniting. Higher CTI values allow lower wall thicknesses, which require good flow properties, notes compounder PolyOne. PolyOne recently introduced high flow, halogen- and phosphorus-free flame retardant, Bergamid® PA6 and PA 6/66 compounds for electrical applications.

OEMs and processors are faced with meeting tougher and tougher specifications for flame retardancy and physical properties, say industry experts. Many industries are showing an increased concern for fire safety. Many products that previously had to meet only the UL94 V2 classification now must meet the more restrictive V0 classification. In addition, many applications must also pass a revised Glow Wire Ignitability Temperature test (GWIT) that is more restrictive than the previous Glow Wire test. In electrical and electronic applications, the Relative Thermal Index (RTI), CTI and GWIT are becoming important tests to consider when designing a product.

Compounding issues

Processors and OEMs increasingly want custom-designed products that meet their specifications, says Mark Jordan, vice-president of sales and marketing at Techmer PM. Speciality compounders can meet this need. However, because both polyamides and flame retardants are difficult to compound, this market is likely to remain a niche area for compounders, says Mr. Jordan.

Polyamides are relatively difficult to compound because they are hygroscopic and because they must be processed at a relatively high temperature. Standard PAs are compounded around 290°C while HTPA are compounded around 310°C. Twin screw extrusion is commonly used. Glass fibre-filled PAs require higher shear than unfilled to disperse high filler levels. Depending on the flame retardant, high compounding temperatures can degrade the flame retardant. Degradation of red phosphorus-based materials can release toxic gases, requiring adequate venting systems.

Feeding and dosing of flame retardants with lower bulk density may require auger screws or stirring mechanisms to prevent bridging. Side feeding is recommended for most flame retardants. Good dispersion of flame retardants is important. Higher loadings and smaller particle sizes are more difficult to disperse, but masterbatches can improve feeding and dispersion.

Halogenated flame retardants

While the environmental impact of halogenated flame retardants continues to be scrutinized, both brominated and chlorinated flame retardants used in PA are expected to continue to have good growth, say suppliers. The polymeric brominated flame retardants typically used in PAs are not extracted from the polymer matrix, reducing concerns about their environmental effect. OxyChem's Dechlorane Plus® chlorinated alicyclic compound is non-blooming and does not form chlorodibenzodioxins or furans. Dechlorane Plus® has good thermal stability and can be processed up to 320°C.

Great Lakes introduced a new brominated polystyrene, Firemaster BP411, for electrical components in January 2004. Albemarle recently introduced Saytex HP-3010, a brominated polystyrene with improved colour stability, thermal stability, and high flow. The new product is targeted for high-temperature polyamides and high-flow applications such as complex, thin-wall parts, notes Sam Thomas, flame retardants global business manager for connectors at Albemarle Corporation. ICL Industrial Products, formerly the Dead Sea Bromine Group, recently introduced F-3100, a high molecular weight polymeric brominated flame retardant for glass-reinforced engineering resins. The product is expected to reduce energy consumption during compounding and pressure during injection moulding, as well as have good melt flow during recycling, says the company. ICL-IP has also introduced the SaFRon 5500 series, proprietary polymeric flame retardants with anti-drip properties, and SaFRon 5251, a dust free polymeric flame retardant for improved conveying and feeding. These products have a processing-aid effect, enabling lower processing temperatures and enhancing melt flow, notes ICL-IP.

Great Lakes' Firemaster CP-44HF flame retardant was originally developed in 2003 to provide higher thermal stability and flow. With the movement to lead-free solder, the product has now been shown to offer improved blister resistance due to its compatibility with HTPA resins. Traditional flame retardants such as brominated polystyrene tend to form blisters on the part surface at the higher temperatures used during lead-free soldering. Blistering occurs because the flame retardant is not completely dispersed through the polymer, but clusters in flame retardant domains where moisture collects and then expands when exposed to high temperatures. Firemaster CP-44HF is a co-polymer of di- and tri-bromostyrene with glycidyl methacrylate. The methacrylate functionality allows greater bonding and compatibility of the flame retardant with the host resin, resulting in improved dispersion and elimination of the flame retardant domain, explains Mr. Andrews.

|

|

Synergists improve thermal stability

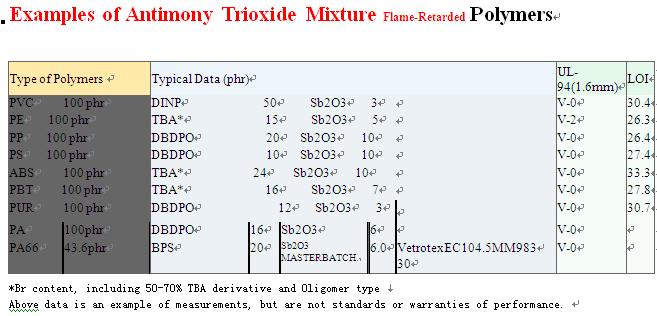

Commercial synergists are well-established in use and can help to increase the thermal stability of a flame retardant package. Kemgard 981, a zinc phosphate complex synergist from Sherwin-Williams, can increase the thermal stability of a PA 6,6 formulation containing a brominated polystyrene flame retardant by 20°C, for example, says John O'Neill, national sales manager at the Sherwin-Williams Company. Kemgard replaces part of the antimony oxide (ATO) synergist in formulations with either Dechlorane Plus or brominated polystyrene flame retardants. Using Kemgard synergist allows formulators to reduce the flame retardant level, which can save costs and possibly improve physical properties. "Some say they can reduce their brominated styrene flame retardant by as much as 10 percent and maintain V0 flammability ratings by using Kemgard 981," reports Mr. O'Neill. Kemgard also results in less corrosive halogen flame retardant systems, he adds.

Firebrake® zinc borates from Luzenac/Borax have traditionally been used as synergists with halogenated flame retardants, and can also be used as synergists with non-halogenated systems. In some formulations, Firebrake can replace ATO or sodium antimonate completely. The use of zinc borates can increase CTI, colour stability and melt flow viscosity stability, as well as alleviate corrosion of processing equipment, says Dr. Kelvin Shen, senior market development manager at Luzenac/Borax.

Halogen-free flame retardants

Red phosphorus is widely used in glass fibre-reinforced PA 6,6 in Europe and Asia, with increasing volumes in the U.S., says Norberto Gatti, sales and marketing manager at Italmatch Chemicals. Red phosphorus is used for applications that can accept its natural red or dark colour, such as industrial switches and other electrical and electronic applications, he adds. Red phosphorus has a high maximum processing temperature of 320°C. Italmatch recommends that red phosphorus be used with dry, virgin PA. With recycled PAs, side reactions may occur with impurities in the recyclate at high processing temperatures, explains Mr. Gatti.

Although red phosphorus is cost-effective, suppliers continue to target halogen-free alternatives that overcome the drawback of the colour imparted to the polymer by red phosphorus. Italmatch recently introduced the Phoslite product line of fully colourable, halogen-free flame retardants based on a low oxidation state of phosphorus. A commercial Phoslite product is available for PC and PC alloys, with products for PA and PBT in development, says Mr. Gatti. Clariant's Exolit OP series of colourless, organo-phosphorus-based flame retardants for glass fibre-reinforced PA were introduced in 2002. Exolit OP 1312 for glass fibre-reinforced PA 6 and PA 6,6 and Exolit OP 1320 for HTPA have been shown to have good cost-performance and have been accepted by the market, says Ruediger Walz, head of marketing, flame retardants, at Clariant's Pigments and Additives division. A commercial plant started up in August of 2004. Exolit has mechanical and electrical properties in the same range or better than the standard halogenated flame retardant, brominated polystyrene, says Dr. Walz. Processing temperatures above 330°C may cause decomposition of the synergists used in Exolit, cautions Dr. Walz. However, studies have shown that increasing temperatures above 330°C does not increase output of resins containing Exolit and that its good melt flow makes higher temperatures unnecessary, he adds. "Phosphorus chemistry-based flame retardants process slightly different than brominated flame retardants. This is a minor problem because customers in this industry are quite experienced and welcome technical training," concludes Dr. Walz.

Melamine-based products include melamine cyanurate, melamine polyphosphate and melamine pyrophosphate. While melamine derivatives have a niche market share, they experienced significant growth last year due to the increasing need for non-halogenated flame retardants, says Florencio Topete, NAFTA director for new business development of plastic additives at Ciba Specialty Chemicals. Melamine derivatives are non-blooming, colourable, produce low smoke density, and have low corrosivity, which extends the lifetime of extruder screws and moulds. Melamine cyanurate is preferred for unfilled PA and also used for mineral filled PA in Europe, Asia, and to a growing extent in the U.S., says Mr. Topete. Melamine polyphosphate is used for glass filled PA. Ciba Specialty Chemicals has patented use of melamine polyphosphate in glass filled PA and is constructing a dedicated Melapur® 200 melamine polyphosphate plant to supply rapidly increasing global demand, says the company. Melamine flame retardants are fluffy powders that have a tendency to bridge during feeding and agglomerate in the melt. Such problems can be avoided by using dosing equipment specifically designed for powders, using masterbatches, or premixing with other additives such as lubricants or stabilizers. A new physical form offers an alternative to overcoming feeding and dosing challenges. Ciba recently introduced an improved dosing version of its melamine cyanurate, Ciba® Melapur® MC XL, and expects to launch an easy-dosing version of its melamine polyphosphate product, Ciba Melapur 200FF, in 2005.

Magnesium hydroxide is an alternative halogen-free flame retardant that can be used in glass-filled PAs. The main drawback of magnesium hydroxide is that it must be used at high levels of 45-55% in order to obtain flame retardant properties. At these high levels, it is difficult to disperse and has a negative effect on physical properties, explains Jim Innes at the U.S.-based consultancy Flame Retardant Associates.

Nanoclays and carbon nanotubes

While most flame retardants have a negative effect on mechanical properties, particularly when added at high levels, nanoclays have been shown to improve both mechanical and flame retardant properties in several resins, including PAs. Nanoclays are used commercially in PAs in combination with either halogenated or non-halogenated flame retardants. Nanoclays have anti-dripping properties and can reduce or eliminate the 'candlelight effect' of glass filled PAs in which the glass fibres act like a candlewick that hastens burning, says Joachim Grossman, vice-president of sales and marketing at Süd-Chemie, which offers Nanofil® nanoclays. Nanofil®SE 3010 and Nanofil® 9 also improve flame retardancy by forming surface char; this application is protected by Süd-Chemie patents in non-halogenated systems, notes Dr. Grossman. Nanoclays are typically treated with organic coatings that aid dispersion but limit the processing temperature to 280°C to 300°C, depending on the organic modifier type. However, some processors have been able to disperse completely nanoclays that have inorganic modifiers added through a proprietary process, says Valerio Cittadini, sales and technical assistant at Laviosa Chimica Mineraria, which offers Dellite nanoclays. Completely inorganic nanoclays have no temperature limitation. Nanoclays can be compounded with twin screw extruders or Buss co-kneaders. Using a masterbatch is recommended for improved dispersion.

Carbon multi-wall nanotubes (CMWNT) are currently in commercial use as a high performance conductive additive for plastics and are being investigated as a possible flame retardant additive, notes Patrick Collins, sales and marketing manager at Hyperion Catalysis International. Studies have shown that CMWNT reduce peak heat release rates, and have a synergistic effect with nanoclays. CMWNT are used at low loadings that would help preserve base resin properties, adds Mr. Collins.

0 comment:

Post a Comment