A miner earlier excluded was confirmed to be among the trapped, authoritative sources said on Saturday morning.

The flooding occurred at around 2:30 p.m. Friday in the coal mine of Huayuan Mining Co. Ltd (formerly known as Zhangzhuang coal mine) in Xintai City, about 150 kilometers south of Jinan, Shandong's capital.

A total of 756 miners were working underground at the time of the flooding and 584 managed to escape after the accident, Xu Qinyu, general manager of the company said on Saturday morning.

Downpours hit the area Friday with a precipitation of 205 millimeters, triggering flash flood and a 50-meter breach of a levee of the Wen river in the region.

Floodwater from the Wen river swamped the coal mine via an old shaft. A 100-millimeter rainfall Saturday night worsened the flooding situation. The rain ended around 7:00 a.m. Saturday.

By 8:50 a.m., the working places under the mine have been all inundated, according to the rescue headquarters.

Wang Ziqi, director of the Shandong coal mine safety administration, said the trapped miners had only slim chances of survival.

Most of the trapped people were from rural areas in Tai'an City and surrounding areas, said Wang Junmin, vice governor of Shandong.

About 2,000 Chinese People's Liberation Army troops, armed police and miners have closed up a 20-meter section of the breached levee of the Wen river.

Li Yizhong, director of the State Administration of Work Safety and Zhao Tiechui, director of the State Administration of Coal Mine Safety have rushed to the site to oversee rescue efforts.

The mine of Huayuan Mining Co. Ltd is a licensed one with an annual capacity of 750,000 tons.

Rescuers carry sand bags to repair the breach of a levee that caused floodwater to swamp a coal mine in east China's Shandong province, on Saturday, August 18, 2007. [Photo: Xinhuanet]

One hundred and seventy-two miners were trapped in a coal mine flooded by surface water in east China's Shandong province.

A miner earlier excluded was confirmed to be among the trapped, authoritative sources said on Saturday morning.

The flooding occurred at around 2:30 p.m. Friday in the coal mine of Huayuan Mining Co. Ltd (formerly known as Zhangzhuang coal mine) in Xintai City, about 150 kilometers south of Jinan, Shandong's capital.

A total of 756 miners were working underground at the time of the flooding and 584 managed to escape after the accident, Xu Qinyu, general manager of the company said on Saturday morning.

Downpours hit the area Friday with a precipitation of 205 millimeters, triggering flash flood and a 50-meter breach of a levee of the Wen river in the region.

Floodwater from the Wen river swamped the coal mine via an old shaft. A 100-millimeter rainfall Saturday night worsened the flooding situation. The rain ended around 7:00 a.m. Saturday.

By 8:50 a.m., the working places under the mine have been all inundated, according to the rescue headquarters.

Wang Ziqi, director of the Shandong coal mine safety administration, said the trapped miners had only slim chances of survival.

Most of the trapped people were from rural areas in Tai'an City and surrounding areas, said Wang Junmin, vice governor of Shandong.

About 2,000 Chinese People's Liberation Army troops, armed police and miners have closed up a 20-meter section of the breached levee of the Wen river.

Li Yizhong, director of the State Administration of Work Safety and Zhao Tiechui, director of the State Administration of Coal Mine Safety have rushed to the site to oversee rescue efforts.

The mine of Huayuan Mining Co. Ltd is a licensed one with an annual capacity of 750,000 tons.

Rescuers use sand bags to repair the breach of a levee that caused floodwater to swamp a coal mine in east China's Shandong province, on Saturday, August 18, 2007. [Photo: Xinhuanet]

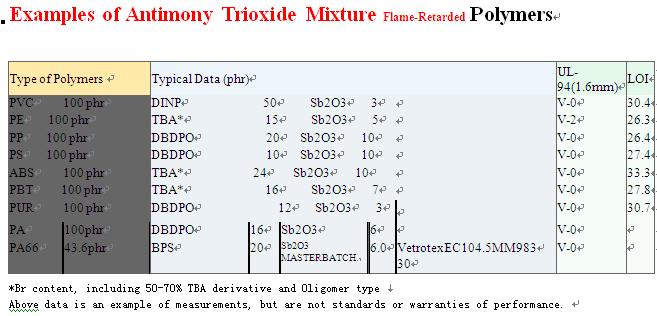

We can supply any quantity and any kind of Antimony products and fire retardant from stock.would you please inform us how many you need and your target price, then we will confirm ASAP. We are sincerely hope to do business with you and establish long term business relationship with your respectable company.

Look forward to hearing from you soon.

Best regards,

Sam Xu

MSN: xubiao_1996@hotmail.com

GMAIL: samjiefu@gmail.com

SKPYE:jiefu1996

Fire retardant masterbatch

...